Textured Soy Protein Food Machinery

1) Direct transmission between motor and gear box,reducing energy consumption.

2) Feeding,main driving device, and rotary cutting device adopt inverters to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life. Segmental assembled screws are applied to more kinds of materials and products

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging molds(dies) and knives seat and bearing knife adjusting system can adjust the knife exactly and swiftly.

Textured Soy Protein Food Machinery

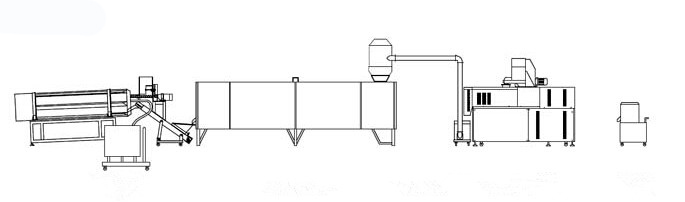

Advanced generation textured vegetarian soy protein tool processing line/fibre soya protein extruder that is superior independently in keeping with our country wide situations at the requirement of market and on the bottom of superior device in switzerland and the united states. this processing line makes use of soybean powder and peanut powder to break spherical protein molecule to form chain protein molecule for that reason developing slice-like fiber form, by manner of powder-grinding, stirring, excessive-temperature, immoderate-pressure and excessive-slicing.

MAIN FEATURES

1) Direct transmission between motor and gear box,reducing energy consumption.

2) Feeding,main driving device, and rotary cutting device adopt inverters to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life. Segmental assembled screws are applied to more kinds of materials and products

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging molds(dies) and knives seat and bearing knife adjusting system can adjust the knife exactly and swiftly.

PARAMETER

| Model | Install Power | Real Power | Capacity | Dimension | Size of workshop | Staff | Delivery |

| SLG65-IV | 110KW | 77KW | 250kg/h | 20x 2.0 x 3.0 | 150 | 2 | 30 |

| SLG65-V | 135KW | 95KW | 300kg/h | 25x 2.0 x 3.0 | 150 | 2 | 35 |

| SLG85 | 210KW | 147KW | 600kg/h | 32x 2.0 x 4.0 | 200 | 3 | 40 |

| SLG95 | 220KW | 155KW | 1200kg/h | 40x 2.0 x 5.0 | 250 | 3 | 50 |

| Steam:500kg/h | Steam:400kg/h |

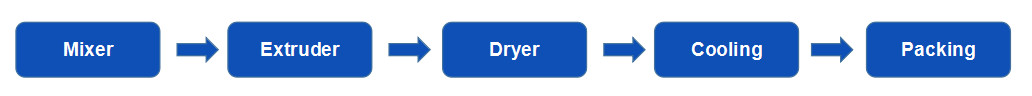

FLOW CHART

PRODUCT SAMPLES

SERVICE

PRE-SALE SERVICES

1).Provide the free consultation of the equipment

2).Provide the standard device and the flow chart

3).According to the clients’ special requirement, offering the reasonable plan and free design helping to

select the equipment.

4).Welcome to visit our factory or the domestic clients’ factory.

SERVICES DURING THE SALES

1).Provide factory layout according to your factory size in advance.

2).Provide the basic formula

3).Inspect the machine before leaving the factory.

4).Oversea installation and commissioning the equipment.

5).Technician will work with your workers together and teach your workers how to install machines, how to

operate machines, how to maintain machines during daily working.