Textured Soy Protein Extruders

1) Direct transmission between motor and gear box,reducing energy consumption.

2) Feeding,main driving device, and rotary cutting device adopt inverters to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life. Segmental assembled screws are applied to more kinds of materials and products

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging molds(dies) and knives seat and bearing knife adjusting system can adjust the knife exactly and swiftly.

Textured Soy Protein Extruders

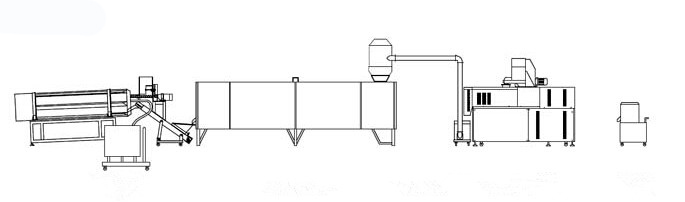

1. This precise textured soya/vegetable protein (tsp/tvp)food processing line use the defatted soya/peanut flour as the uncooked cloth.

2. Textured soya/vegetable protein (tsp/tvp)meals device's foremost characteristic:low production value and excessive earnings.

3. Three. thru this textured soya/vegetable protein food product gadget processing line, the materials can be reorganized and formed into distinctive shapes such as pipe, stick, ball and greater.

4. Four. as this line makes extra concentrated and healthful protein, it has grow to be the maximum popular line inside the international

5. Five. the screws are made via alloy metal and special craft, the screw existence is longer, uses building block machine shape, may additionally integrate willfully

6. The pressured lubrication system, by means of assured device transmission longer lifespanvisible vehicle-temperature controlling machine, make the temperature-controlling to be more direct-viewing, parameter to be greater specific.correct textured soya/vegetable protein (tsp/tvp)food processing line

MAIN FEATURES

1) Direct transmission between motor and gear box,reducing energy consumption.

2) Feeding,main driving device, and rotary cutting device adopt inverters to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life. Segmental assembled screws are applied to more kinds of materials and products

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging molds(dies) and knives seat and bearing knife adjusting system can adjust the knife exactly and swiftly.

PARAMETER

| Model | Install Power | Real Power | Capacity | Dimension | Size of workshop | Staff | Delivery |

| SLG65-IV | 110KW | 77KW | 250kg/h | 20x 2.0 x 3.0 | 150 | 2 | 30 |

| SLG65-V | 135KW | 95KW | 300kg/h | 25x 2.0 x 3.0 | 150 | 2 | 35 |

| SLG85 | 210KW | 147KW | 600kg/h | 32x 2.0 x 4.0 | 200 | 3 | 40 |

| SLG95 | 220KW | 155KW | 1200kg/h | 40x 2.0 x 5.0 | 250 | 3 | 50 |

| Steam:500kg/h | Steam:400kg/h |

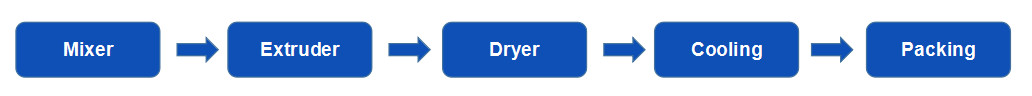

FLOW CHART

PRODUCT SAMPLES

SERVICE

PRE-SALE SERVICES

1).Provide the free consultation of the equipment

2).Provide the standard device and the flow chart

3).According to the clients’ special requirement, offering the reasonable plan and free design helping to

select the equipment.

4).Welcome to visit our factory or the domestic clients’ factory.

SERVICES DURING THE SALES

1).Provide factory layout according to your factory size in advance.

2).Provide the basic formula

3).Inspect the machine before leaving the factory.

4).Oversea installation and commissioning the equipment.

5).Technician will work with your workers together and teach your workers how to install machines, how to

operate machines, how to maintain machines during daily working.