Puff Corn Snacks Machine

1. Puff corn snack machine adopts twin screw extrusion technology

2. Machines adopt stainless steel 304

3. All machines are automatically control

4. All motors use the Siemens brand

Puffed Corn Snacks Machine

Puffed leisure food production line can automatically finish raw materials preparation, extrusion, shaping, cutting, drying, and flavoring at a time. This production line has the advantages of more machine choice, flexible and diverse configurations, a wide range of raw materials applications, numerous product varieties and easy operation.

FEATURE

1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system, and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for a forced cooling effect, ensuring extruder operates safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice but also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratios, whole-expanded and half-expanded as different types of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

PARAMETER

| Model | Install Power | Real Power | Capacity | Dimension | Size of workshop |

| SLG65 | 74KW | 52KW | 140-150kg/h | 23x 2.0 x 3.0 | 150 |

| SLG70 | 114KW | 82KW | 240-260kg/h | 28x 2.0 x 3.0 | 150 |

| SLG85 | 180KW | 140KW | 400-500kg/h | 35x 2.5 x 5.0 | 200 |

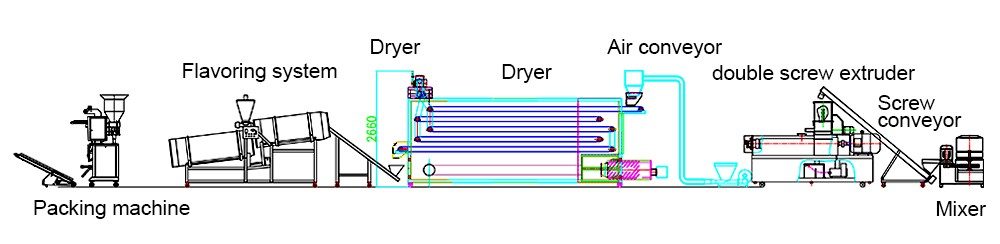

FLOW CHART

Mixer→ Screw conveyor → Twin screw extruder→ Air conveyor(Hoister)→ Electric dryer → Hoister → Oil Sprayer→ Flavoring roller(drum) → Cooling conveyor

SAMPLES

MOULDS