Core Filling Puffed Snack Food Machine

1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

Core Filling Puffed Snack Food Machine

Core filling puffed food making machine adopts corn, rice, wheat, oat, barley etc as ingredients to make puffed snack. Through friction of screw and barrel, the grains are cooked in the jam center snack food making machine.The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

FEATURE

1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

PARAMETER

| Model | Install Power | Real Power | Capacity | Dimension | Size of workshop | Staff | Delivery |

| SLG65 | 74KW | 52KW | 140-150kg/h | 23x 2.0 x 3.0 | 150 | 3 | 30 |

| SLG70 | 114KW | 82KW | 240-260kg/h | 28x 2.0 x 3.0 | 150 | 3 | 30 |

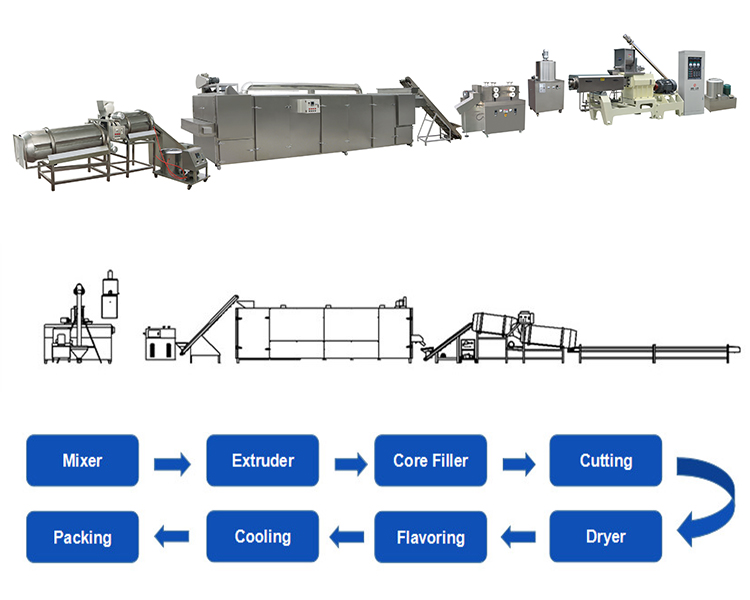

FLOW CHART

Mixer→ Screw conveyor → Twin screw extruder→Core filler→Cutter→ Hoister→ Electric dryer → Hoister → Oil Sprayer→ Flavoring roller(drum) → Cooling conveyor

SAMPLES

SERVICE

Pre-sale services

1).Provide the free consultation of the equipment

2).Provide the standard device and the flow chart

3).According to the clients’ special requirement, offering the reasonable plan and free design helping to

select the equipment.

4).Welcome to visit our factory or the domestic clients’ factory.

Services during the sales

1).Provide factory layout according to your factory size in advance.

2).Provide the basic formula

3).Inspect the machine before leaving the factory.

4).Oversea installation and commissioning the equipment.

5).Technician will work with your workers together and teach your workers how to install machines, how to

operate machines, how to maintain machines during daily working.