Macaroni Processing Lines

Compact structure novel design and stable performance,developed on the base of like produces and requirements in the world market.It realizes high automation,convenient operation,low energy and small floor space,that assures all working procedures from feeding flour to finished once.The investment for this line is only one tenth of that larger size equipment ,especially suitable to small-size or self-owned enterprise.

Macaroni Processing Lines

As we all know, customers like the pliable and chewy pasta. Europe and America manufature all adopt vacuum technique into the extruder to reach this demand.This industrial pasta making device/line/plant/industry pasta making machine/macaroni pasta making system/pasta production line can be used to provide shell, spiral, square tube, circle tube shapes;compact shape novel design and strong performance,developed on the bottom of like produces and necessities in the world market.it realizes high automation,convenient operation,low energy and small ground area,that assures all running techniques from feeding flour to completed as soon as.

TECHNICAL ADVANTAGES

Compact structure novel design and stable performance,developed on the base of like produces and requirements in the world market.It realizes high automation,convenient operation,low energy and small floor space,that assures all working procedures from feeding flour to finished once.The investment for this line is only one tenth of that larger size equipment ,especially suitable to small-size or self-owned enterprise.

PARAMETER

| Model | Install Power | Real Power | Capacity | Dimension | Size of workshop | Staff | Delivery |

| DLG110 | 105KW | 73KW | 120-150kg/h | 22x 2.0 x 3.0 | 150 | 3 | 35 |

| DLG150 | 190KW | 135KW | 250-300kg/h | 30x 2.0 x 3.0 | 150 | 3 | 40 |

| DLG160 | 250KW | 175KW | 350-400kg/h | 35x 2.5 x 4.2 | 200 | 3 | 55 |

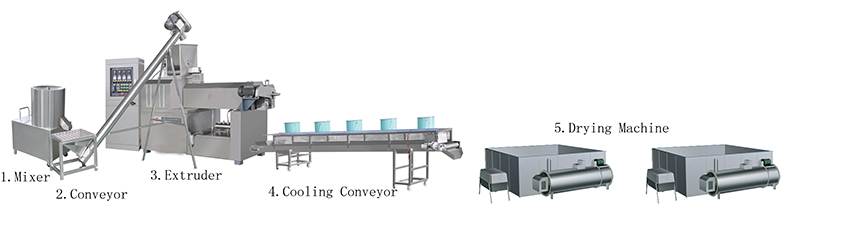

FLOW CHART

Mixing system---Extrusion system----Cutting system---Drying system---Cooling system--Packing system

PASTA DIE

RAW MATERIALS

Adopts wheat flour, corn flour etc as raw materials

SAMPLES

SERVICE

Pre-sale services

1).Provide the free consultation of the equipment

2).Provide the standard device and the flow chart

3).According to the clients’ special requirement, offering the reasonable plan and free design helping to

select the equipment.

4).Welcome to visit our factory or the domestic clients’ factory.

Services during the sales

1).Provide factory layout according to your factory size in advance.

2).Provide the basic formula

3).Inspect the machine before leaving the factory.

4).Oversea installation and commissioning the equipment.

5).Technician will work with your workers together and teach your workers how to install machines, how to

operate machines, how to maintain machines during daily working.