Extruder Instant Rice Machine

This production line is improved to avoid the loss of nutritional elements in the rice which is made by the traditional rice processing. It has characters of high automatic, easy operation, energy saving and environmental protection. The raw materials for nutrition rice extrusion line can be rice, black rice, buckwheat and other grains(broken rice and rice bran can be reused). You can also add additional nutrient components, such as vitamins, minerals etc. After extruding, forming and drying, you can get the nutritional artificial rice, which is eaten same as natural rice.

Extruder Instant Rice Machine

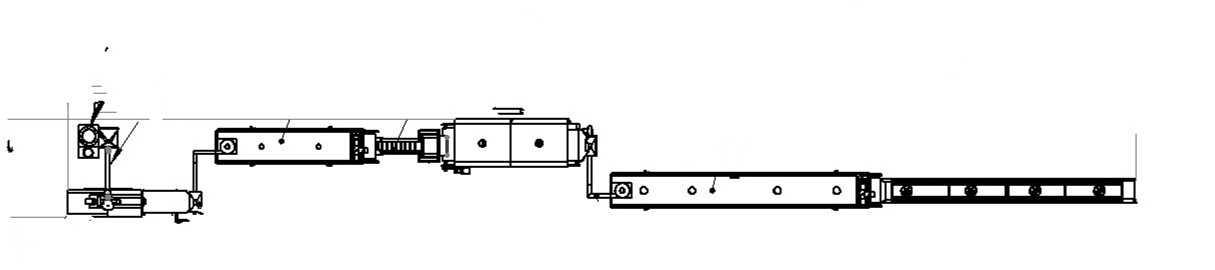

This extrusion nutritional artificial rice machine is one of the newly developed double-screw extruding techniques of our company. Extrusion nutritional rice machine not only can process grain materials, like buckwheat,oats,etc.but strengthen the nutrients to produce multi-functional nutritional healthy food,such as slimming grain powder, buckwheat powder, black seame paste,red chinese date thick soup,etc.

PARAMETER

| Model | Install Power | Real Power | Capacity | Dimension | Size of workshop | Staff | Delivery |

| SLG70 | 110KW | 77KW | 180-200kg/hour | 22x 2.0 x 3.0 | 100 | 2 | 30 |

| DLG100 | 105KW | 73KW | 150-180kg/hour | 22x 2.0 x 3.0 | 100 | 2 | 30 |

| DLG150 | 190KW | 135KW | 300-350kg/hour | 30x 2.0 x 3.0 | 150 | 3 | 40 |

| DLG150-II | 300KW | 210KW | 600-700kg/hour | 40x 3.5 x 4.0 | 200 | 4 | 55 |

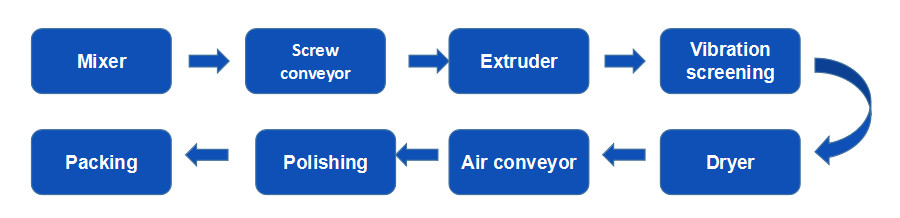

FLOW CHART

Mixing system---Extrusion system---- -Drying system---Cooling system---Packing system

Voltage in China

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers’ Local voltage according to different countries.

Machine materials

All the machine are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function

Raw materials

Adopts corn flour,rice power ,wheat powder etc. as materials.

PRODUCT SAMPLES

SERVICE

PRE-SALE SERVICES

1).Provide the free consultation of the equipment

2).Provide the standard device and the flow chart

3).According to the clients’ special requirement, offering the reasonable plan and free design helping to

select the equipment.

4).Welcome to visit our factory or the domestic clients’ factory.

SERVICES DURING THE SALES

1).Provide factory layout according to your factory size in advance.

2).Provide the basic formula

3).Inspect the machine before leaving the factory.

4).Oversea installation and commissioning the equipment.

5).Technician will work with your workers together and teach your workers how to install machines, how to

operate machines, how to maintain machines during daily working.