Dog Food Machine

1. Dog food machine adopts twin screw extrusion technology

2. From raw material to final product all are automatically

3. It produces different sizes and shapes of dog food in one machine

4. Dod food machine can produce food for different age groups

5. We design the machine according to customer demand

Dog Food Machine

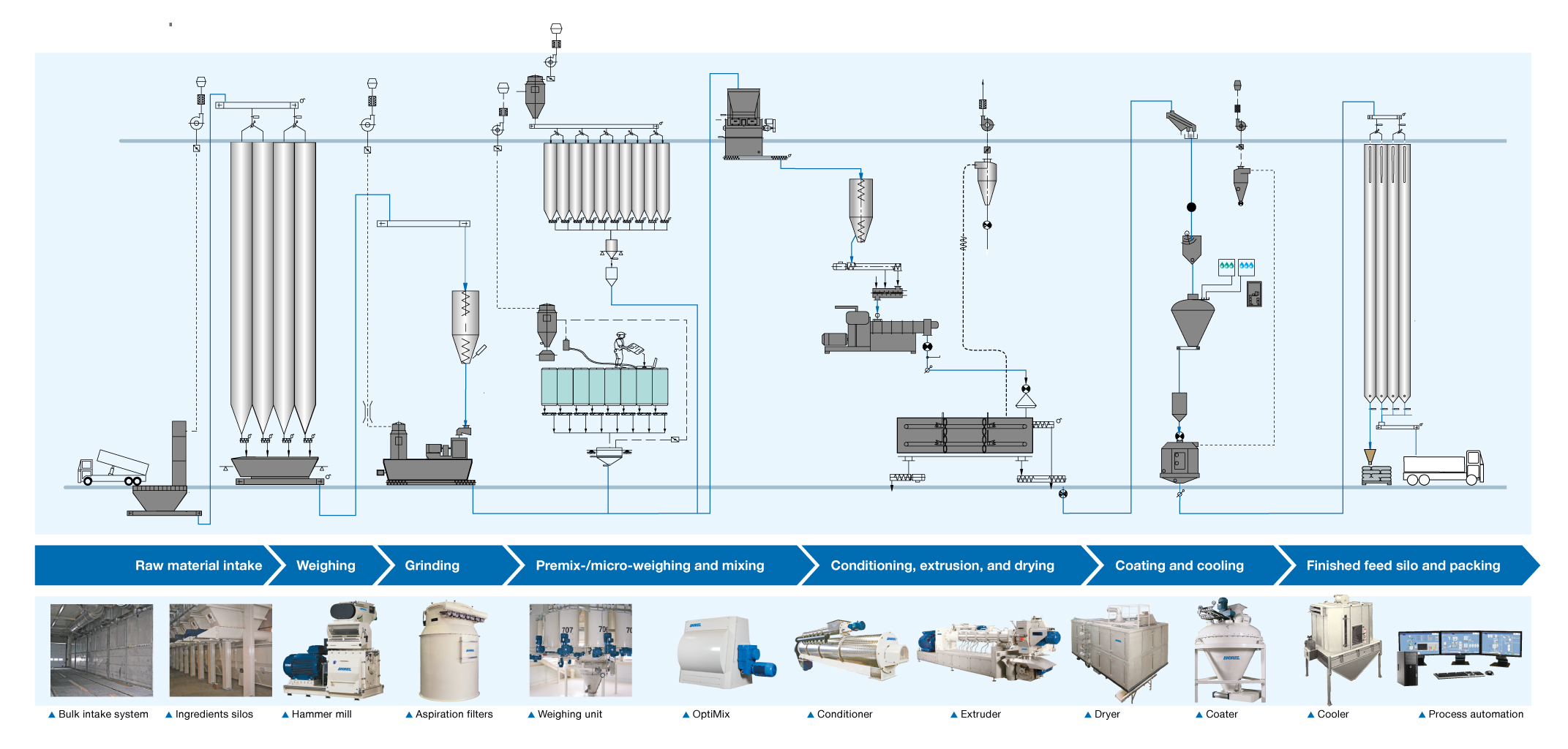

The layout of the dog food-making machine:

Just tell us your demand: 1. What capacity do you need?

2. What's your warehouse dimension?

3. What main raw material do you want to use?

We will give you professional solutions for the dog food making machine.

Dog food machine Parameters:

Model | Consume Power | Capacity | Dimension | Size of workshop |

SLG65 | 50KW | 120-150kg/h | 20x 2.0 x 3.0 | 150㎡ |

SLG70 | 80KW | 220-300kg/h | 25x 2.0 x 3.0 | 150㎡ |

SLG85 | 160KW | 400-600kg/h | 37x 3.0 x 5.0 | 300㎡ |

SLG95 | 155KW Steam:600kg/hour | 1000-1500kg/h | 60x 3.0 x 6.0 | 400㎡ |

SLG120 | 195KW Steam:1100kg/hour | 2000-2200kg/h | 80x 4.0 x 7.5 | 600㎡ |