Corn Flakes Production Process

1.The main extruder adopts frequency speed controlling with high automation.

2.The screws are made of the stainless steel and special craft, which has the advantage of durable usage, high pressure,and longer life.

3.The forced lubrication system ,which can guarantee the equipment transmission life longer.

4.Auto-temperature control system and self-cleaning ,which makes it more convenient.

5.It has the widest range of applications and can produce different products with different equipment and models.

Corn Flakes Production Process

Corn flakes produced by Corn flakes cereals making extruder machine production line are a kind of breakfast with high nutritional value. Corn flakes extruder always service as breakfast cereal mixed with milk of coffee. But it can also be a kind of leisure snacks. This corn flakes making machine production line is highly automatic and easy to operate. Just by changing the dies or choosing suitable production process, different shapes breakfast cereals can be available such as ring ,ball ,flake,star,letter etc .

THE ADVANTAGE OF CORN FLAKES EXTRUDER

1.The main extruder adopts frequency speed controlling with high automation.

2.The screws are made of the stainless steel and special craft, which has the advantage of durable usage, high pressure,and longer life.

3.The forced lubrication system ,which can guarantee the equipment transmission life longer.

4.Auto-temperature control system and self-cleaning ,which makes it more convenient.

5.It has the widest range of applications and can produce different products with different equipment and models.

PARAMATER

| Model | Install Power | Real Power | Capacity | Dimension | Size of workshop | Staff | Delivery |

| SLG65 | 130KW | 90KW | 100-120kg/h | 35x 2.0 x 3.0 | 150 | 3 | 30 |

| SLG70 | 150KW | 105KW | 140-150kg/h | 35x 2.0 x 3.0 | 150 | 3 | 30 |

| SLG85 | 210KW | 150KW | 300-320kg/h | 40x 2.0 x 4.0 | 200 | 3 | 40 |

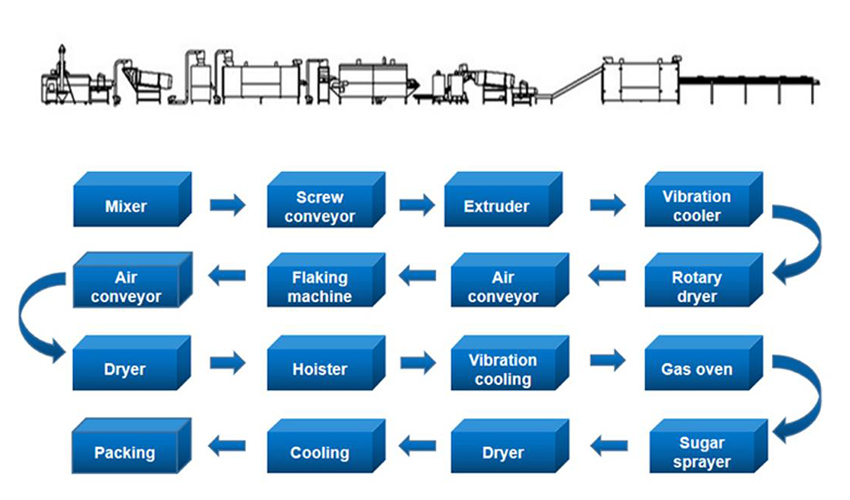

THE WHOLE LINE OF CORN FLAKES

1.Processing line: Mixer→Screw conveyor→Twin screw extruder→Vibrating feeder→Drum type dryer→Air conveyor→Flaking machine→Air conveyor→Dryer→Hoister→Vibrating feeder→High-temperature inflated oven→Flavoring line→Dryer→Cooling machine

2.Voltage: Three phases: 380V/50Hz, Single phase: 220V/50Hz. we can make it according to customers' Local voltage according to different countries.

SAMPLES

SERVICE

Pre-sale services

1).Provide the free consultation of the equipment

2).Provide the standard device and the flow chart

3).According to the clients’ special requirement, offering the reasonable plan and free design helping to

select the equipment.

4).Welcome to visit our factory or the domestic clients’ factory.

Services during the sales

1).Provide factory layout according to your factory size in advance.

2).Provide the basic formula

3).Inspect the machine before leaving the factory.

4).Oversea installation and commissioning the equipment.

5).Technician will work with your workers together and teach your workers how to install machines, how to

operate machines, how to maintain machines during daily working.