Breakfast Cereals Production Machine

1) Direct transmission betwe en motor and gear box,reducing energy consumption.

2) Feeding,main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life.Segmental assembled screws are applied tomore kinds of materials and products

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly.

Breakfast Cereals Production Machine

Breakfast cereal food and corn flakes food are crispy food which might be produced via breakfast cereal process line using grist as primary cloth.it is speedy and nutritional food with given structure in granule shape, flake shape adn animal shape. its super characteristic is containing plentiful compound carbohydrate and meal fibre. breakfast cereal cannot handiest enhance masses of microelement which include diet and mineral, however also be delivered with cocoa powder, sugar powder, honey, and maltose. you can experience it immediately by using blending with coffee, milk, yoghourt or useful drink. youngsters can devour breakfast cereal as candy crispy snack. there are also natural corn flakes,sweet corn flakes and salty corn flakes in keeping with distinct flavors.

MAIN FEATURES

1) Direct transmission betwe en motor and gear box,reducing energy consumption.

2) Feeding,main driving device, and rotary cutting device adopt inverter to adjust the speed with more powerful drive, stable running, and low consumption.

3) Screw is made of alloy steel with long life.Segmental assembled screws are applied tomore kinds of materials and products

4) Automatic lubrication system can lower down power consumption and prolong the life.

5) Double screws feed equal materials forcibly.

6) Hanging mould and knives seat and bearing knife adjusting system can adjust the kniver exactly and swiftly.

PARAMETER

| Model | Install Power | Real Power | Capacity | Dimension | Size of workshop | Staff | Delivery |

| SLG65 | 70KW | 50KW | 120-150kg/h | 20x 2.0 x 3.0 | 150 | 3 | 30 |

| SLG70 | 110KW | 80KW | 220-250kg/h | 25x 2.0 x 3.0 | 150 | 3 | 30 |

| SLG85 | 180KW | 140KW | 400-500kg/h | 32x 2.0 x 4.0 | 200 | 3 | 40 |

Processing flow

Mixing system; Extrusion system; Flaking system; Drying system; Flavoring system; Drying system; Packing system

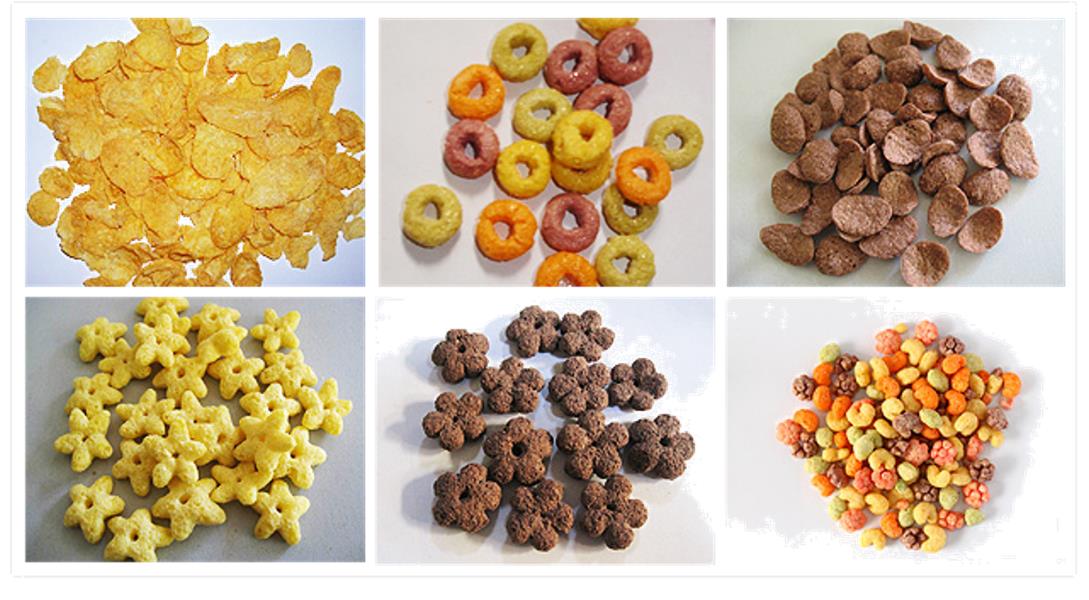

SAMPLES

Variety shapes are available for ball, tube, stick, ring, fruit loop, star, wheel and flower and heart shape by adjusting the mould in the extruder ; corn flakes; cereal snacks.

SERVICE

Pre-sale services

1).Provide the free consultation of the equipment

2).Provide the standard device and the flow chart

3).According to the clients’ special requirement, offering the reasonable plan and free design helping to

select the equipment.

4).Welcome to visit our factory or the domestic clients’ factory.

Services during the sales

1).Provide factory layout according to your factory size in advance.

2).Provide the basic formula

3).Inspect the machine before leaving the factory.

4).Oversea installation and commissioning the equipment.

5).Technician will work with your workers together and teach your workers how to install machines, how to

operate machines, how to maintain machines during daily working.