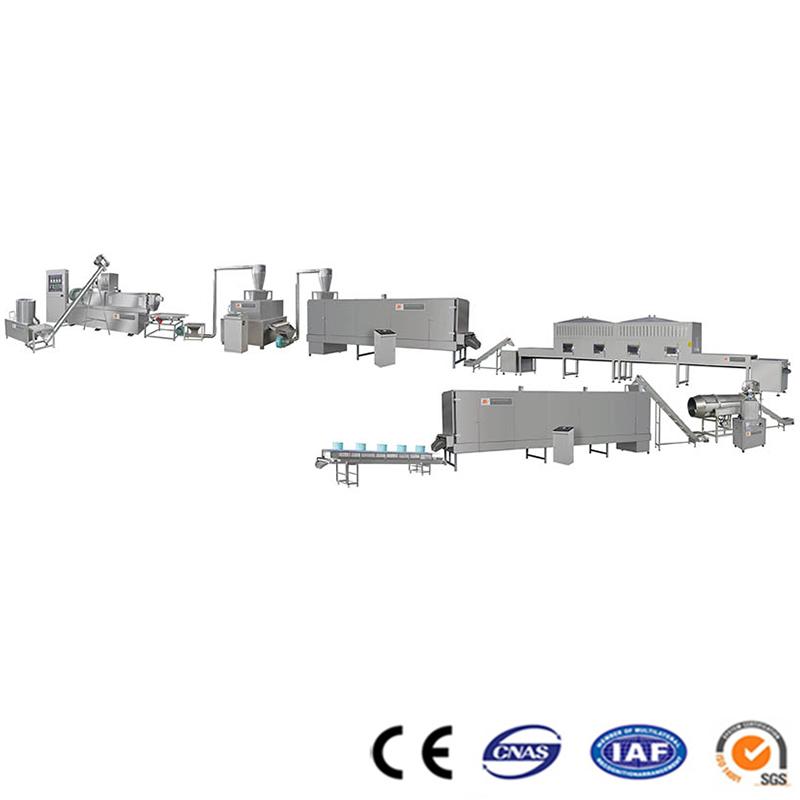

Fried Type Cheetos Making Machine-manufacture,factory,supplier from China

(Total 24 Products for Fried Type Cheetos Making Machine)

Cheetos,Kurkures are manufactured by blending corn and water. The mixture is heated under pressure, and then extruded through a die.

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

Nik naks Snack Processing Machine use the corn grits flour as raw material. It can produce different size of Nik naks. It can produce baking type and fried type product

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

Baked cheetos kurkures snack production machine line uses special kind of extruder. After baking machine, the cheetos kurkures snack food is more crispy and healthy.

Contact Now

Baked cheetos extruder machine line is one of our main products. It uses a special kind of extruder with high quality.

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

This industrial pasta making machine/line/plant/industry pasta making machine/macaroni pasta making machine/pasta production line is produced by single-screw extruder through extruding cooking; the macaroni pasta can be different shapes like shell, spiral, square tube, circle tube, and so on. After drying, the maxaroni pasta needs frying to get expanded.

Contact Now

Puff Snack Food machine Corn Puff Snack Extruder Puffed Rice Process Line is a new type of extruding food machine studied and developed by ourselves on the basis of learning from advanced technology in the world so that its technical performance and quality of products both reach to the most advanced in the world.

Contact Now

kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. They are made by a special extrusion process. The corn grits are moisturized in the flour mixer with water and fed to the rotary head extruder. In the extruder, due to the two rotary plates, the corn grits are squeezed and twisted to curls shapes.

Contact Now

Tortilla chips making machine line uses twin screw extruder to produce high quality tortilla chips. The machine line has different kind of models for customers to choose.

Contact Now

Puff Snack Food machine Corn Puff Snack Extruder Puffed Rice Process Line is a new type of extruding food machine studied and developed by ourselves on the basis of learning from advanced technology in the world so that its technical performance and quality of products both reach to the most advanced in the world.

Contact Now

This industrial pasta making machine/line/plant/industry pasta making machine/macaroni pasta making machine/pasta production line is produced by single-screw extruder through extruding cooking; the macaroni pasta can be different shapes like shell, spiral, square tube, circle tube, and so on. After drying, the maxaroni pasta needs frying to get expanded.

Contact Now

Modified Starch Making Machine Line adopts grains as raw material to produce high quality modified starch food. It can be applied in chemistry and food industry.

Contact Now

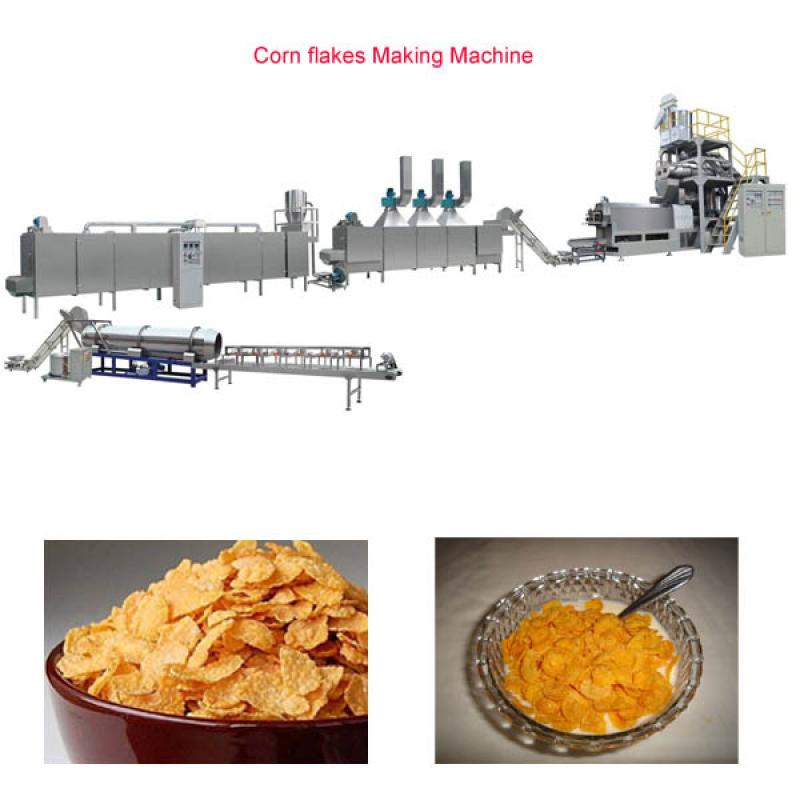

Corn Flakes Making Machine

cereal breakfast/corn flakes is one kind of crispy food, with the advantages of hard to be steeped broken and strong grain taste. It is crispy flakes which are made from corn meal and the other grains powder

Contact Now

This industrial pasta making machine/line/plant/industry pasta making machine/macaroni pasta making machine/pasta production line is produced by single-screw extruder through extruding cooking; the macaroni pasta can be different shapes like shell, spiral, square tube, circle tube, and so on. After drying, the maxaroni pasta needs frying to get expanded.

Contact Now

Relate News

Kurkure Cheetos MachineRaw material:Corn gritsProduct: Kurkures, Nik naks, CheetosCapacity:120kg/hour, 240kg/hour,360kg/hour and 480kg/hourMachine material: SUS304Screw Material: 38CrMoAl, Alloy steel Kurkure Cheetos Machine Description:The kurture cheetos machine is a made by a special kind of extruder. The kurkure cheetos machine uses extruder equipped with two rotary plates for squeezing and twisting the raw material. Then the extruder makes the curl shapes of the food.

Cheetos kurkures snack food machineCheetos kurkures snack food machine is one of our hot-selling products. The machine line adopts a special kind of extruder to extrude the raw material. There have frying type and drying type. The frying type can make the food more crispy. The drying type makes the food more healthy. The kurkure cheetos machine uses extruder equipped with two rotary plates for squeezing and twisting the raw material. Then the extruder makes the curl shapes of the food.

Fried Chips MachineMain raw material: Corn flourCapacity:120-150kg/hour, 200-220kg/hour, 300-320kg/hourControl: PLC Control. Touch screen OperateElectric Parts Brand: SIEMENSMachine material: SUS304 Product description:Our fried chips machine is popular for its high quality. Fried chips machine can produce crispy snack food. The raw material is mainly corn flour. After extruding, the food can be made into triangle or round shape. It will be fried in the continuous fryer which makes it crispy. With seasoning in the flavoring roller, the snack food will be tasty.

Last week, our customer from Mali came to our factory for visiting. He sent us an inquiry about 60-80kg/h pasta macaroni machine line. The machine line includes mixer, single screw extruder, cooling conveyor, dryer, and conveyors to connect each machine.We introduced the function of each machine to him and answered his questions about our machine.The pasta macaroni machine line can produce various shape macaroni such as fusilli, shell, macaroni, penne. The mixer has fan blades insides to mix the raw material evenly.We use single screw extruder for producing it.

Artificial Rice Machine Description:Artificial rice kernel machine can produce resemble rice. The raw material of fortified rice kernel machine is usually broken rice, or with other cereals. The product is full of nutrition and vitamins such as vitamin A and vitamin B. With the pursuing of food nutrition and the development of technology, it is suitable for modern enterprise and customers.

Bread crumbs is a broadly used as meals components, it is able to be used for frying the floor of food, consisting of: fried hen, fish, seafood (shrimp), hen legs, hen wings, onion jewelry, and so on., its taste is crispy, tender, delicious and nutritious.These days bread crumbs is in particular produced by means of extrusion era.

We have finished production of pasta macaroni making machine line. This machine line cost around 45 days for production.The machine line is 300kg/h including mixer, screw conveyor, extruder, cooling conveyor, first dryer, elevator, second dryer, cooling conveyor.Pasta macaroni machine line uses single screw extruder with vacuum system. It can produce fusilli, vermicelli, spiral, shell, penne and other short cut pasta macaroni food with high quality.Here are some samples.

Dog Food Machine Description:The dog food machine can produce different kinds of pet food like: Dog food, cat food and other animal food. The pet food machine also name dog food machine, cat food machine and animal feed machine.This machine is suitable for Pet food factory. Product Features:Dog Food Machine Features:Our Dog Food Machine the characteristics of small floor area, flexible placement, easy operation, low energy consumption and large output.

As China fortified rice machine manufacturer, we were in this discipline more than two decades. For fortified rice system,there's special ability type and we can produce rice by dual screw extruder or single screw extruder. we will equip the suitable fortified rice making machines for you in line with your requirement and very last product.

Textured Soya Protein MachineMain raw material: Defatted soy Meal, Soy protein,Wheat glutenProduct: Textured Soya Protein(TSP), Textured Vegetable Protein(TVP)Capacity:260kg/hour, 600kg/hour and 1000kg/hourMachine material: SUS304Electric parts brand: SIEMENS Product description:Textured soya protein machine uses low temperature soy bean meal as main raw material to produce all kinds of textured protein food with high nutrition. As the textured soya protein is tasted like meat so it is welcomed by vegetarians.

The benefit of corn flakes extruder1.the primary extruder adopts frequency speed controlling with high automation.2.the screws are made from the stainless-steel and unique craft, which has the gain of long lasting usage, high strain,and longer existence.Three.the pressured lubrication device ,that can guarantee the system transmission existence longer.Four.auto-temperature manipulate device and self-cleaning ,which makes it more handy.5.it has the widest variety of packages and can produce different merchandise with special system and models.

Making The Manner To Thrill Choosy EatersIndustry estimates positioned the worldwide Puppy population someplace around Four hundred million and as human populations retain to skyrocket, so will The range of household pets.The nutritional and digestive requirements for these animals varies Significantly relying, now not only at the Species of the pet being fed, however Additionally upon their age, activity stage, Temperament, and fitness.